In the field of modern transportation construction, high-pressure airless spraying is a widely used marking method. As a generator of sprayed fluid in high-pressure airless spraying equipment, the nozzle affects the atomization effect of the fluid and the overall application quality of the marking.

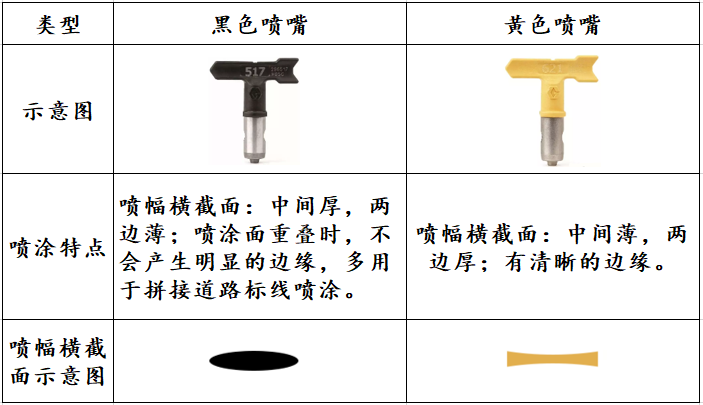

▲ Black nozzles and yellow nozzles commonly used in high-pressure airless spraying equipment

The nozzle determines not only the flow of paint (paint thickness) that leaves the gun when the trigger is pulled, but also the width of the spray produced by the gun (spray range). Therefore, choosing the right and appropriate nozzle can not only make the construction efficient and smooth, but also a kind of maintenance for the equipment and extend the service life of the equipment.

Basic information such as flow rate and spray width can be judged by the three-digit code marked on the nozzle.

Taking the 517 nozzle as an example, the first digit "5" multiplied by 2 means that the maximum width that can be achieved by the spray width is 10 inches (10*2.54=25.4 cm). The last two digits "17" indicate the caliber of the nozzle, which determines the flow rate leaving the nozzle, in 1‰ inches, which is 0.017 inches (0.017*2.54=0.43 mm).

* 1 inch = 2.54 cm

▲Information on the three-digit code on the nozzle

In addition, we need to understand the relationship between spray width and nozzle diameter:

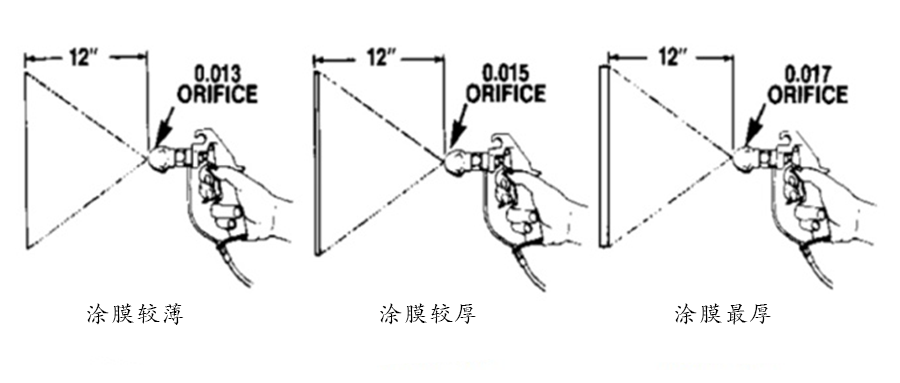

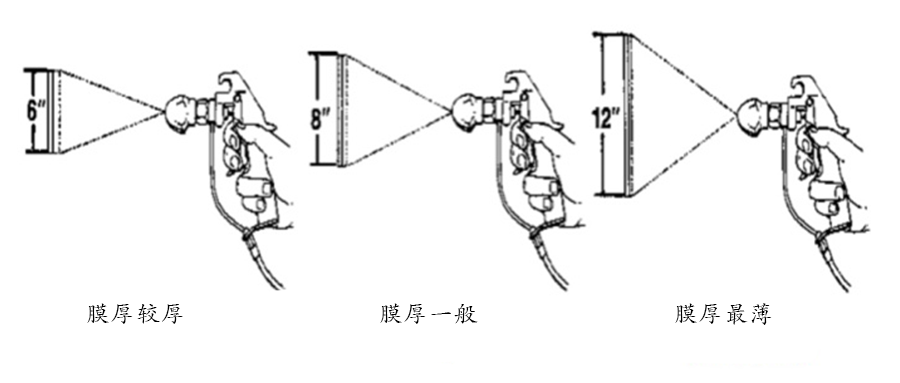

(1) Spray thickness of the same spray width and different calibers.

(2) For nozzles of the same caliber and different spray widths, the thickness of the film sprayed by the small diameter nozzle shall be thick.

To choose the right nozzle for the spraying traffic marking project, it is necessary to consider not only the actual road conditions, but also the two elements of flow and spray amplitude.

Tips

• Choose the appropriate nozzle size according to the spraying material. If low-viscosity materials (such as varnishes, colorants, etc.) are used, a low-flow nozzle should be used, while high-viscosity materials (such as oil-based coatings) should be used. Nozzle size selection can be made according to the coating manufacturer's recommendations.

• Nozzle selection according to airless road scribing equipment. If you plan to use multiple guns in your marking work, select a nozzle size that matches the rating of multiple guns for airless road scribing equipment.

▲ Multiple airbrush pictures

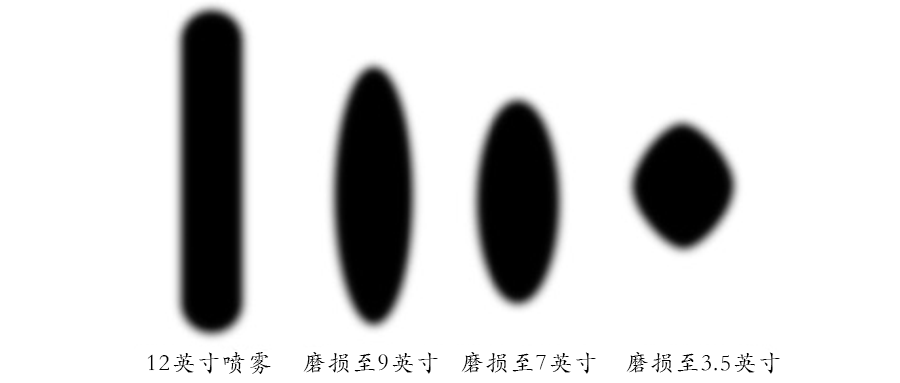

After choosing the right nozzle, in addition to using it correctly, you should also know and judge the use of the nozzle. The nozzle material is tungsten carbide, although it is the most wear-resistant material in airless nozzles, if it is used for too long, the use is not standardized, or the paint contains corrosive substances, etc., it will cause wear and tear to the nozzle

▲Nozzle wear diagram

In the process of marking, equipment users need to pay attention to the nozzle situation, and if abnormalities are found, they need to be checked and replaced in time. Worn nozzles will not only affect the spraying effect, but also affect the scribing equipment and delay the construction period.

Tips

• After the nozzle wears, the pore size becomes larger, and the paint cannot be atomized normally, which will lead to insufficient adhesion with the road surface and the marking line is easy to fall off;

• After the nozzle wears, the spray width becomes smaller, which affects the construction efficiency and causes unnecessary waste of coating.

• After the nozzle is worn, the spray width is unstable, which will lead to substandard marking thickness and reticle line type.

Summary: According to different road conditions, spraying materials and marking width requirements, choose the appropriate nozzle model and color, and combine the matching nozzle with the spray gun to better play the efficiency of airless road marking equipment and complete the road traffic marking construction operation.