Compared with high-quality MMA two-component reticles, hot melt reticles have a series of problems in their applications:

About the construction methodDuring hot melt construction, it is necessary to use liquefied gas to heat the material temperature to more than 180 °C, and there are fire and explosion hazards in open flame operation, and burns and scalding accidents often occur. In addition, the burning personnel feed up to 120-200 bags (25kg/bag) per day, mostly using walk-behind construction, which may lead to occupational diseases such as lumbar spine problems and alopecia areata all year round. Hot melt construction requires primer oil, which increases the process and is cumbersome to construct.In contrast, MMA two-component marking is constructed at room temperature, with a daily material of about 20 barrels (25kg/barrel), and spraying is self-sufficient, which is safe, easy, clean and convenient to construct, without primer, saving the process, improving efficiency and reducing costs.Hot melt coatings have poor weather resistance, are brittle at low temperatures, have poor flexibility, and crack and age quickly when the temperature difference between day and night is large. This not only affects the aesthetics of the paint, but also leads to its easy water seepage, dirt seepage, and even flake peeling, affecting the life of the marking.In contrast, high-quality MMA two-component markings have good weather resistance, do not absorb ultraviolet rays, are not affected by external temperature differences and thermal expansion and contraction, and do not have aging and cracking.

▲ Hot melt cracking

▲ Hot melt cracking

The hot melt marking has extremely poor adhesion on the cement pavement.

High-quality MMA two-component coatings have better adhesion and are more competitive than hot melt pavements on asphalt pavement and cement pavement with qualified grades.Hot melt markings will have uneven reflection during construction or after a period of time. This is due to the insufficient strength of the hot-melt main material, making it difficult to bond the glass beads firmly. When the wheel is crushed frequently, the glass beads can easily fall off. or when the road surface temperature and air temperature are high, the reticle will soften and press the glass beads into the reticle paint film, which will directly affect the reflective effect and reflective life. In addition, if there is a difference in material temperature during the construction process, the degree of settling of glass beads will also be inconsistent, which will affect the uniformity of reflection.In contrast, high-quality MMA two-component coatings form a dense paint film surface through a chemical cross-linking reaction that makes the glass beads bond strongly, resulting in longer-lasting reflections of the markings and a higher retroreflective brightness coefficient during (rainy) nights and wet roads. In the same case, after a period of traffic wear and tear, the reflection of high-quality MMA two-component is generally uniform, and there will be no shadow of a large number of glass beads falling off like hot melt, which will affect the aesthetic effect of night vision.

▲ Construction unit: Sichuan Zhongzhi Highway Traffic Engineering Co., Ltd

▲ Construction site: Pengmei section of S103 Highway

▲ Construction unit: Guangzhou Municipal Maintenance Office

▲ Construction location: Huanshi East Road, Yuexiu District, Guangzhou

About repainting the markings

The strength of the hot melt main resin is poor, in order to prolong the life of the marking, only the thickness of the stroke or the number of recoats can be increased, and the thickness of each stroke is generally 1.5-2mm. If the thickness exceeds the standard, it will bring driving safety hazards. If it is controlled within the standard thickness, the marking line will be very thin when recoated, and the paint will solidify quickly after cold, so that the glass beads cannot be bonded firmly, resulting in the marking line not reflective.In contrast, high-quality MMA two-component spraying has a thickness of about 0.7mm each application, and after 2-3 years of construction, the two-component can be directly recoated, or the old line can be directly re-fused, and high-quality MMA two-component spraying is the most ideal choice for maintenance construction.After hot melt aging, it is necessary to remove the line before drawing. The hazards of water removal/mechanical line removal are: increased construction costs, waste of water resources, damage to the road surface and irreversible, high cost of line removal garbage recycling, road congestion, and increased management costs on the owner's side.In contrast, if the MMA two-component spraying marking needs to be rerouted, it can be directly sprayed and covered with MMA two-component coating paint, which has high efficiency and long life, and does not damage the pavement.

▲ Water removal lines cause great damage to the pavement and waste water resources

▲ For the part that needs to be rerouted, two-component covering and spraying can be used, which is highly efficient and does not damage the pavement

About low-carbon environmental protection

The VOC of hot melt bottom oil exceeds the standard, the combustion of liquefied gas releases carbon dioxide to pollute the environment, and the dust of coatings and line removal also pollutes the environment, which is not conducive to energy conservation and emission reduction. Frequent marking and removal of hot melt markings need to close the road, which can easily cause traffic jams, fuel consumption, and air pollution caused by automobile exhaust.In contrast, high-quality MMA two-component does not contain any harmful substances, and the coating has a high solid content of nearly 100%, which is basically non-volatile, green and environmentally friendly, and is in line with the national "dual carbon goal" policy.The long-lasting reflective properties of high-quality MMA two-component coatings are particularly excellent in environments where street lights are lacking or poorly lit, and can significantly improve road edge definition. Therefore, the number of street lights can be appropriately reduced and the brightness of the street lights can be adjusted, and the street lights can be turned off after midnight, which can save a lot of electricity. At the same time, it can also reduce the installation of road studs, contour markers, curb light strips and a large number of electroluminescent facilities, so as to reduce the burden on the country and the government and save money.Hot melt markings come off when shoveling snow.In contrast, premium MMA two-component reticles have strong adhesion and are not affected by snow shoveling and snow melting agents. Hot melt markings are easily soft and brittle under the influence of temperature, and are not wear-resistant. Especially on multi-vehicle vehicles, ramps, and roads with high traffic flow, wear out quickly and shorten the lifespan.In contrast, high-quality MMA two-component markings are harder than cement, and the anti-wear life can even be as long as 5-10 years under conventional road conditions and when the amount of paint meets the standard.Hot melt markings contain plasticizers, which will migrate, making the surface of the markings sticky and easy to stain dust. Especially in the south, the temperature is high, and the stain resistance of the marking line is poor.In contrast, high-quality MMA two-component coatings cure to form a dense paint film, which can effectively prevent the penetration of pollutants, and the coating is not affected by air temperature, and the surface will not become sticky, and will not adhere to sediment and dust. And, after rain and snow, rinsing with a sprinkler truck or high-pressure water gun, the markings will be as smooth as new.

The non-slip particles of the hot melt reticle are not firmly bonded and easy to fall off, and the anti-slip effect is poor.In contrast, high-quality MMA two-component anti-slip markings can firmly adhere to anti-slip particles, and the anti-slip value can still be greater than 55BPN after half a year, with a long anti-slip life, especially the good anti-slip effect of zebra crossings, which can better reduce accidents.On March 15, 2018, the reticle line fell off and the reticle was not reflective

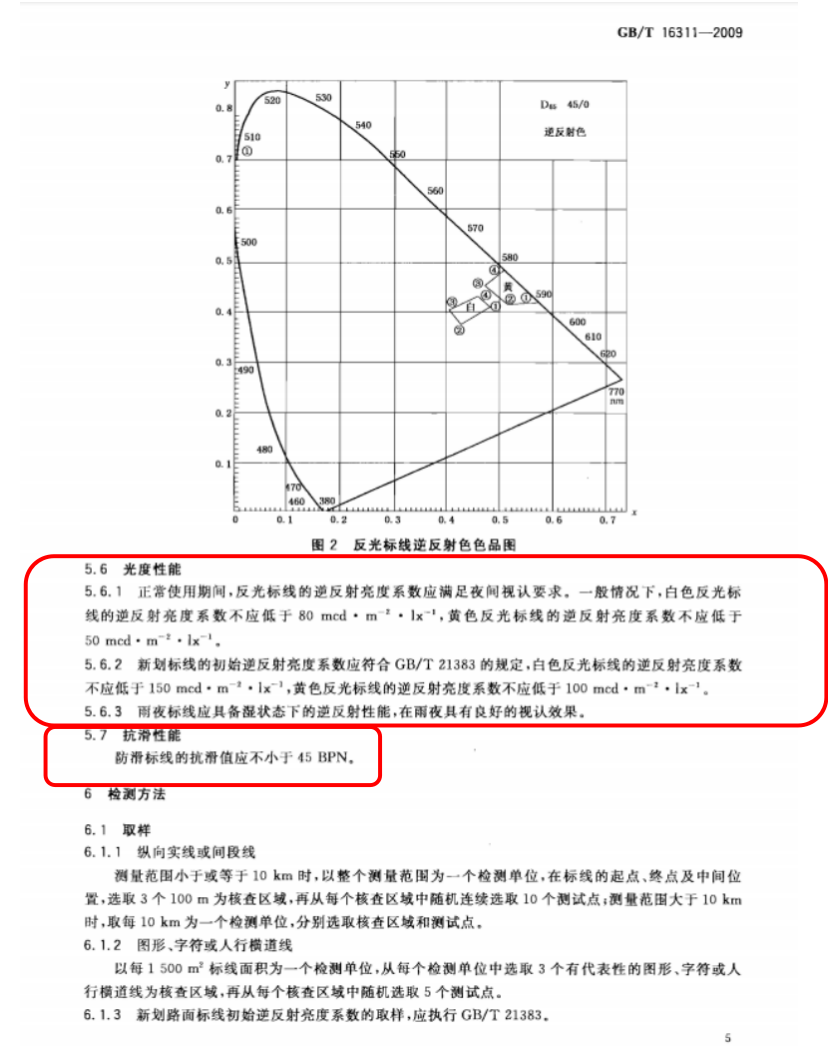

▍ Reticle reflection and anti-slip are national mandatory standards

Attached: GB/T 16311-2009 Road Traffic Marking Quality Requirements and Testing Methods

Sanwin two-component overall solution has strong international competitiveness

Looking at the world, two-component labeling systems are widely used in cold climate regions such as Northern Europe, Canada, and the United States. However, MMA two-component pavement marking coatings and equipment are generally considered very expensive compared to other materials. In addition, this advanced marking method requires engineers with more than ten years of experience to carry out construction. In terms of equipment, the price of Denmark's Borum and Germany's Hofmann equipment is more than 100-2 million. These specially designed equipment for curing agents significantly increase the equipment cost of road marking works. Because the structure of the equipment is very complex, the maintenance cost is high in the later stage. Before and after sales, long-term technical communication needs to be maintained, all of which limit the popularization and application of this advanced marking method.

| Why Choose Roadzilla® Methyl Methacrylate (MMA) Two-Component Traffic Marking System? This high-performance MMA traffic coating outperforms all products on the road. If you're tired of getting your paint on area markings, roads, intersections, and other high-traffic areas torn by snowplows and traffic jams, consider Roadzilla. This two-component methyl methacrylate system features a high-quality polymer blend that provides exceptional durability even in the harshest environments. MMA has been used in Canada and throughout Europe for over 20 years to provide long-lasting safety while minimizing re-marking. In the United States, you can find our Roadzilla in some of the most challenging environments, including Alaska and much of the Pacific Northwest. These areas rely on methyl methacrylate traffic marking systems to withstand the constant impact of snowplows on roads and parking lots. Are you tired of repainting area markings and roads every few years? Contact us to learn more about how the Roadzilla MMA Traffic Marking System can provide a solution for your most demanding traffic and area marking needs. |

▲ The official website of the Aexcel brand in the United States explains

Focusing on China, since Sanwin modified the American Graco equipment to support MMA two-component marking in 2003, after several years of updates and iterations, it has become the most complete and durable MMA two-component supporting construction equipment in China, with a price of between 10-200,000 yuan. At the same time, Sanwin has a complete teaching system in coating equipment and construction through years of engineering practical accumulation, which can help customers quickly cultivate professional and technical personnel and solve various construction problems in a timely and efficient manner, so that customers have no worries after purchasing. In addition, Sanwin coatings are internationally leading in quality, and their cost performance is far better than similar brands in Europe and the United States. Therefore, we firmly believe that in the future, whether at home or abroad, Sanwin traffic safety materials will be more popularized and applied, contribute to the realization of the vision of "zero accidents", and make roads safer.

Marking Coatings Market Outlook

The road marking coatings market is expected to be worth USD 5 billion by the end of 2023. The global demand for road marking coatings is expected to grow at a CAGR of 4.8% to reach USD 8 billion by 2033.

Increasing investment in infrastructure boosts demand for road marking coatings

Infrastructure Development: The construction and maintenance of roads, highways, and other transportation infrastructure are key drivers of the road marking coatings market. As countries continue to invest in infrastructure projects, the demand for road marking coatings is expected to increase.

Growing Urbanization: Rapid urbanization and increasing population density are driving the demand for more extensive and efficient road networks. This has led to an increase in demand for road marking coatings for the construction of new roads and highways, as well as the maintenance of existing infrastructure.

Smart road technology presents lucrative opportunities

Adoption of Smart Road Technology: The adoption of smart road technologies, such as embedded sensors and reflective coatings, presents significant opportunities for the road marking coatings market. These technologies enable road markings to be used for real-time traffic monitoring, automated vehicle guidance, and other innovative applications

Growth in Emerging Markets: The market for road marking coatings in emerging markets such as Asia Pacific, Latin America, and the Middle East is expected to witness significant growth. Increasing infrastructure investments, increasing urbanization, and growing demand for road safety are driving this growth.

Focus on Environmental Sustainability: With increasing concerns about environmental sustainability, there is a growing demand for eco-friendly road marking coatings that reduce carbon emissions and minimize environmental impact. This presents an opportunity for manufacturers to develop and promote sustainable road marking coating formulations.

Advancements in Coating Technology: Advancements in coating technology, such as formulations, have enabled manufacturers to develop high-performance road marking coatings that offer superior durability, visibility, and slip resistance. These technological advancements provide manufacturers with opportunities to differentiate their products and gain a competitive edge.

What is driving the demand for road marking coatings

The demand for road marking coatings has been increasing, thanks to its various properties, such as wear resistance, gloss, and the richness of reflective properties and application scenarios.

These markings are used on streets, berms, highways, curbs, driveways, sidewalks, parking lots, and airports, and have a wide range of applications in zebra crossings, speed bumps, dividers, landing markers, intersections, highways, local roads, intersections, and more.

It can also be used to help provide directions and turn signals to the driver. In addition, the chemical plays a crucial role in traffic control.

New developments in marking coatings are driving the growth of this market. Researchers and scientists are coming up with innovations such as organic-inorganic hybrid polymer latex for highly durable traffic marking coatings, reactive line markings that utilize solar energy, and more. Such new developments in road marking coatings are driving the growth of this market.

Increasing awareness about road safety to drive the road marking coatings market

Due to people's busy schedules, limited travel time, and faster lifestyles. Furthermore, due to the driver's lack of awareness of their surroundings, this increases the stress, which in turn leads to a large number of traffic accidents.

To ensure that drivers can see safety signs and directions directly, quality road marking coatings play a crucial role. These markings provide the driver with information about the conditions ahead and indicate where passage is allowed. Due to the highly reflective nature of the reflective reticle, it also helps the driver in adverse weather conditions and at night.

Global Road Marking Coatings Market Regional Insights

In the global road marking materials market, the dominating region is North America. North America holds a significant market share due to well-developed infrastructure, extensive road networks, and stringent regulations regarding road safety and marking. The presence of major economies such as the United States and Canada, along with ongoing infrastructure development projects, contributes to North America's dominance in the market.

The fastest-growing region in the global road marking materials market is Asia Pacific. The Asia-Pacific region is experiencing rapid urbanization, population growth, and increasing government investments in infrastructure development. Increasing investments in smart street marking systems to improve road safety are expected to create new opportunities for market players. Countries such as China, India, and Southeast Asian countries are witnessing significant road construction projects and expansion of transportation networks, which is driving the demand for road marking materials. Additionally, the implementation of safety regulations and the focus on improving road safety standards further drive the market growth in the region.

Global Road Marking Coatings Key Market Trends

Increasing Use of Reflective Materials: Reflective road marking materials are becoming increasingly popular due to their ability to reflect light from the vehicle's headlights, thereby improving visibility and safety during night driving. The use of reflective materials in road markings can help drivers clearly identify lane markings and improve overall road safety.

▲Comparison of Sanwin navigation aid reflective markings and non-Sanwin markings/Ezhou Huahu Airport·2021

Increasing Use of Road Marking Materials in Smart City Projects: The concept of smart cities is becoming increasingly popular worldwide, and road marking materials play a crucial role in the development of intelligent transportation systems. Road markings equipped with sensors and connectivity technology are used for intelligent traffic management, pedestrian safety, and vehicle-to-infrastructure communication.

In the next ten years, with the improvement of people's awareness of traffic safety and the rapid changes of the transportation network, the road marking coating industry is ushering in its spring like a rising star.