There are many reasons that affect the life of markings and colored pavements, the main of which is that the pavement is not properly treated before construction. Since two-component markings are usually applied without primer, the pre-treatment of the pavement becomes particularly important. Because foreign matter on the road surface will reduce the adhesion between the paint and the road surface, causing the markings and colored pavement to crack or even fall off.

▲Because the road surface near the curb is not well treated, the markings are relatively more serious

The most basic role of road surface treatment is to remove all pollutants that may affect the quality of the project, including the hot melt old wire that may be powdered and peeled off, so that the paint can better adhere to the road surface. Pavement treatment is one of the important factors that determine the success or failure of the construction of markings and colored pavement

▲Due to improper pavement treatment, the markings of the cement pavement fell off in a large area

Cement pavement accounts for a large proportion and a wide range in our country's grassroots transportation network, and it is the most likely road surface to cause markings and colored pavement to peel off, so special attention needs to be paid to. Because the concrete and mortar of cement pavement still contain moisture and maintain strong alkalinity (pH 12~13) for a long time after laying, special attention must be paid to the construction of cement pavement: ensure that the cement pavement has been fully maintained, so that its moisture content is less than 6%, pH is less than 9.5, and foreign matter such as oil and floating slurry layer have been completely removed.

■ Moisture

The drying time of cement pavement varies depending on the composition and season, and the table below illustrates this more clearly.

■ Alkaline

The alkaline components inside the cement will slowly rise to the surface along the cracks inside the cement or with the moisture in the cement. This will lead to bleaching, coating peeling, discoloration and other problems, and pickling must be used to neutralize the alkalinity.

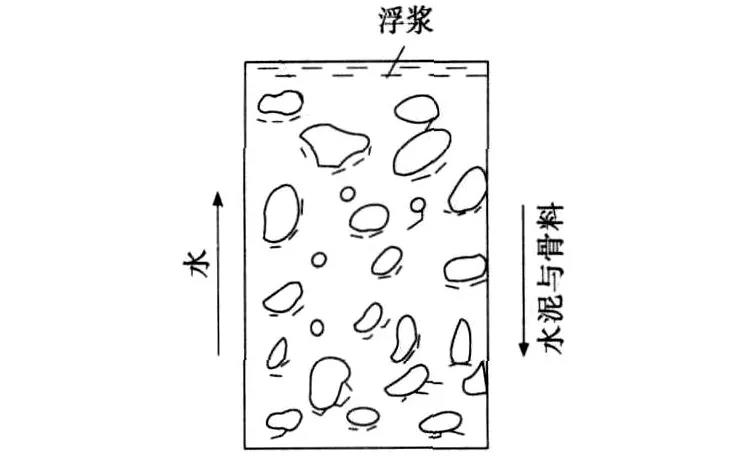

■ Floating slurry layer

Calcium oxide in cement reacts with water or carbonic acid to form a floating slurry layer that does not have strength. Usually, we remove the floating slurry layer by mechanical sanding. But in some cases, we have to apply a sealing primer before we can carry out the coating application.

Whether it is cement or asphalt, we have a standard pavement treatment procedure to ensure that the pavement is clean, dry, free of oil and other contaminants, and the following are the key steps.

The purpose of sanding is to remove dirt from the road surface or the surface of old lines. Sweeper is a commonly used sanding equipment.

▲Use a sweeper to polish the road surface and old lines

■ Blow-dry

Use a hair dryer to blow away dirt, sand, dust and other dirt on the road surface to keep the construction area clean.

▲Use a hair dryer to clean the construction area

Use a thread remover to remove the old markings to prevent the old lines from falling off after covering, causing the markings or colored paving to fall off.

▲Use a wire remover to remove the old wire

We must recognize that there is a risk in keeping the old wire and overcoating it directly. Although two-component markings can be overapplied directly, we do not recommend doing so on hot melt markings that are aging or at risk of shedding. In some cases, in order to control costs, the construction party retains the old hot melt markings, resulting in a significant reduction in the life of the two-component markings, which is not worth the loss.

▲Due to the powdering of the bottom hot melt marking, the coated two-component marking line will fall off

Removing old lines is often an indispensable step in road cleaning, and it is also a link that requires high investment time and labor costs. We recommend using the Graco GrindLazer wire remover system for more efficient decommissioning issues. Our technical support team can also provide expert solutions for all Graco wire stripper applications.

A good start is half the battle, pavement treatment is the beginning of construction, and it is also a key link that affects the life of markings and colored pavement. As long as you pay more attention here, I believe you will be able to make high-quality two-component projects.